Extreme knitting with 1st/2nd Graders!

Tracy Bromwich

This is pretty off-topic from my usual weaving posts. But I thought my fiber-loving friends - especially those with young, crafty kids - might enjoy this. If you're looking for an ambitious project for yourself - or one that you can do with your little one - read on!

My kids' elementary school holds a fundraising auction each Spring in which the students of each classroom collaborate to create an item to be sold. In the first few weeks in February, 6 hours of class time are devoted to the activity, which is organized and supported by parents and implemented by the students. This is the fourth year I've had the honor of coordinating the classroom project. For anyone interested, you can find some mention of the previous projects I've undertaken with classrooms here: LJ Indigo, AJD Orange and BS Yellow.

In previous years, I have worked with students on hand-dyeing techniques and used the material they created to sew or weave a blanket. This year, I wanted to develop a project that would allow them a greater role in crafting the item. Along with dyeing the material, I wanted to give them the opportunity to work with it, as well. The thick, massive yarn that is all the rage right now seemed perfect for a group knitting project. It works up quickly and - aside from it's weight - is fairly easy to manipulate. But how does one approach knitting something substantial with a group of children unfamiliar with knitting?

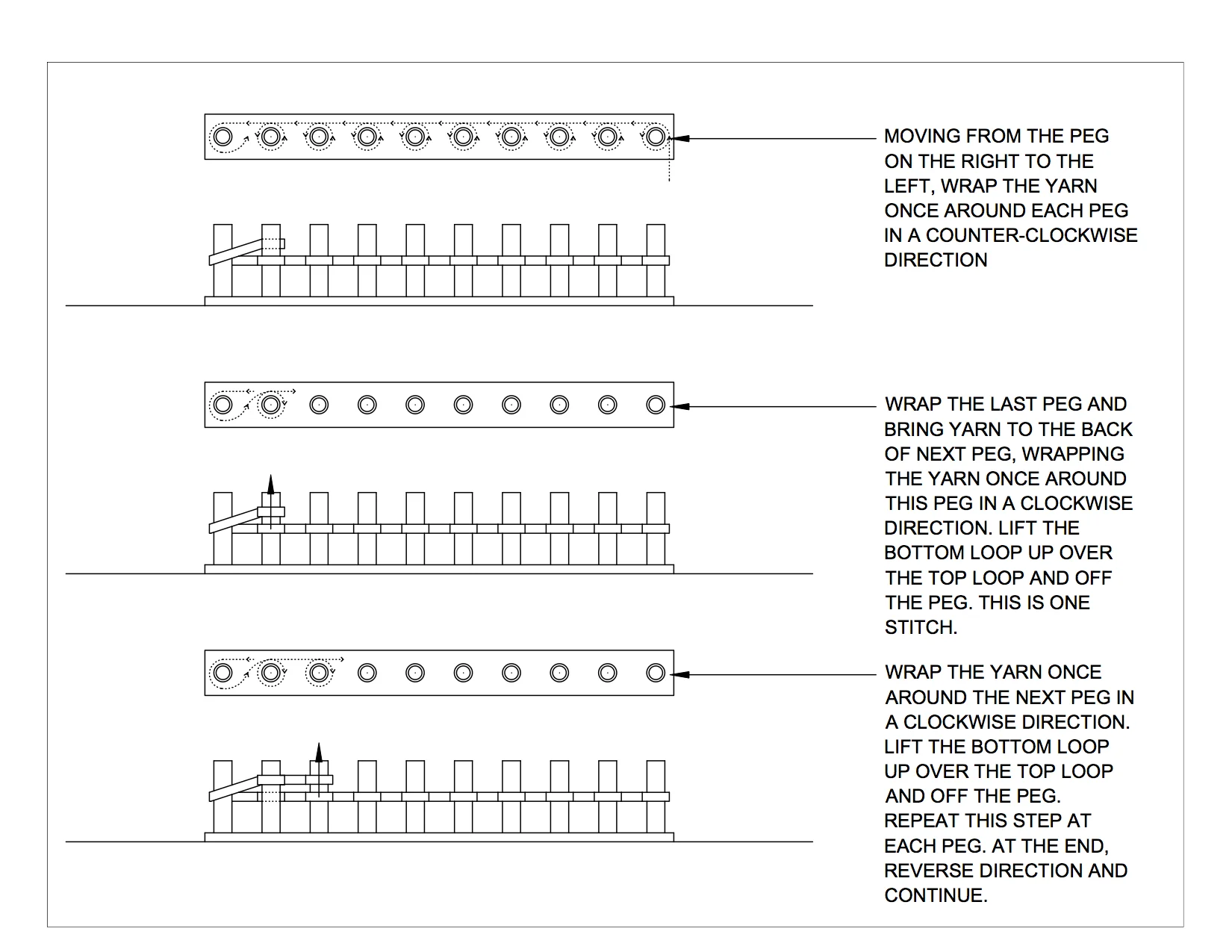

As often happens, I was inspired by one of my older daughter's interests. At 10 years old, Sophia is now becoming more comfortable knitting on needles. But a few years ago - when she had the interest in making knitted creations but found knitting needles to be frustrating - she discovered loom knitting to be a great alternative. Though specific methods vary, this technique basically involves wrapping a length of yarn around a series of pegs in one direction- from peg #1 to peg #8, for example - and repeating this action in the opposite direction - from peg #8 to peg #1. A knitted stitch is created by lifting the bottom loop up over the top loop and off the loom. Below is a rough sketch - I hope it helps to demonstrate the principle.

I thought of introducing this type of knitting to the class. Then I wondered: what would be the result of increasing the scale of both the yarn and the loom? Could I make a large loom that would enable them to knit a blanket with some massive yarn? With my daughter's teachers on board with the idea, it was time to start testing some natural dye colors and building a loom!

For the dye, the teachers' only criteria was that it be a natural dye. They didn't have any requirements for color or dye materials used and thought that it might be good to offer a number of alternatives to the kids and ask them to select their favorite. To simplify my job of creating samples - I really just wanted to get on with the business of knitting - I bought the Aquarelle Liquid Natural Dye Kit from Botanical Colors and dyed up a bunch of small skeins of wool. My younger daughter, Nora, and I collaborated on the winding, mordanting, dyeing and presentation board.

The top row shows the results of working with each dye alone; the bottom row shows the results of combining colors or adding soda ash.

Before I began building the loom, I experimented with some massive, bulky yarn. I started by knitting a throw blanket with a brand from my local yarn shop on US 50/25 mm needles. I needed to determine the correct gauge for the project, which would inform the size and spacing of the pegs on the loom.

The yarn I chose for the classroom project was the incomparable K1S1 extremely large yarn by Little Dandelion. I chose this yarn - which is specifically designed for high-end interior applications - for it's softness and resilience. It has just the right amount of felting to prevent the pilling I was already experiencing with the yarn I had experimented with. The 5 1.5 kg bumps arrived from New Zealand just in time to test out the concept!

As I was sketching ideas for how to attach 1" PVC pipe sections to a 2x4, my husband reminded me of the equipment I had in storage that already had pegs attached at the approximate spacing I needed. That saved me some time! I brought out the warping board that attaches to my Glimakra loom, secured the two pieces end to end - et viola! The pegs were a little too narrow for the gauge I needed so I did end up going to the hardware store for a 1" PVC pipe, which I had cut into 6" sections. A rubber gasket the diameter of the base of each peg was placed to keep the pipe section from popping off. I also added caps so the knitting would remain on the pegs while we worked.

Testing the prototype.

We started with an e-wrap cast on and a simple knit stitch. Sophia, Nora and I worked together on the knitting. We were already had a good length after just 15 minutes!!!

With this proof of concept we presented our idea to the class. They chose the dye - Saxon Blue, a formulation of indigo dye - and we prepared the yarn for the classroom work. To get it ready for dyeing, I wound each 1.5 kg bump into a large skein - tying it in several places to keep the yarn in place - and simmered it in my huge pot with a mordant of 6 oz aluminum sulfate per the Aquarelle Liquid Natural Dye Kit instructions.

The yarn - prepped for dyeing.

Of all the steps involved in this project, dyeing was the single most time consuming. I worked with small groups of students and several helpful parent volunteers to measure the dye, monitor the temperature and duration of the dye bath and carefully manipulate the yarn to achieve an even color whilst preventing further felting of the yarn. The entire process took about 3 hours per skein of yarn. Once the dye had struck and the water was nearly clear, I allowed the yarn to cool inside the dye bath for several more hours before removing it from the bath. Once it reached room temperature, I proceeded with washing and rinsing. Fortunately, this dye takes wonderfully to wool. There was little to no dye that needed to be rinsed from the fibers. Once dry, we wound it back onto the cone and were ready for knitting.

This photo shows the yarn after being placed in the dye bath.

This shows Nora stirring the pot during the initial heating of the dye bath.

Progress...

Here is the yarn - dyed, dry, and wound back onto the cone and ready to knit with.

The blanket was knit entirely by the 26 students and 2 teachers of HD Green on the loom - which we assembled in their classroom retreat space. Students first learned a simple knit stitch on a small hand-held loom with DK weight yarn. In turn, each student and both teachers knitted rows using the large scale yarn on the large loom. Knitting continued until the blanket reached it's final size: approximately 60" x 130". We reached this size with about 3-1/2 of the 5 1.5 kg bumps we started with. We plan to use the remaining yarn to knit a much smaller blanket for their classroom reading area.

The blanket is super soft with excellent thermal properties. It has a surprisingly consistent stitch given the number of different hands involved in it's creation. It is generously sized - perfect to be shared. Folded in half it fits nicely over the foot of a bed. Folded many times, it can serve as a floor cushion.

Some of the kids took to the process very quickly. Others less so. Everyone needed a little coaching on the proper tension for the yarn when wrapping the pegs. There were a few kids convinced they couldn't do it. It was very rewarding to talk them through each step and watch as it "clicked" and they began working with confidence and ease. Most spoke of how the work was so much more enjoyable with the thick, soft yarn on the large loom as compared with the hand-held loom. As the blanket grew in size, it was irresistible. Children would curl up in it, pile up on top of it, remark on it's weight and softness. I think they are all very proud of what they have created!